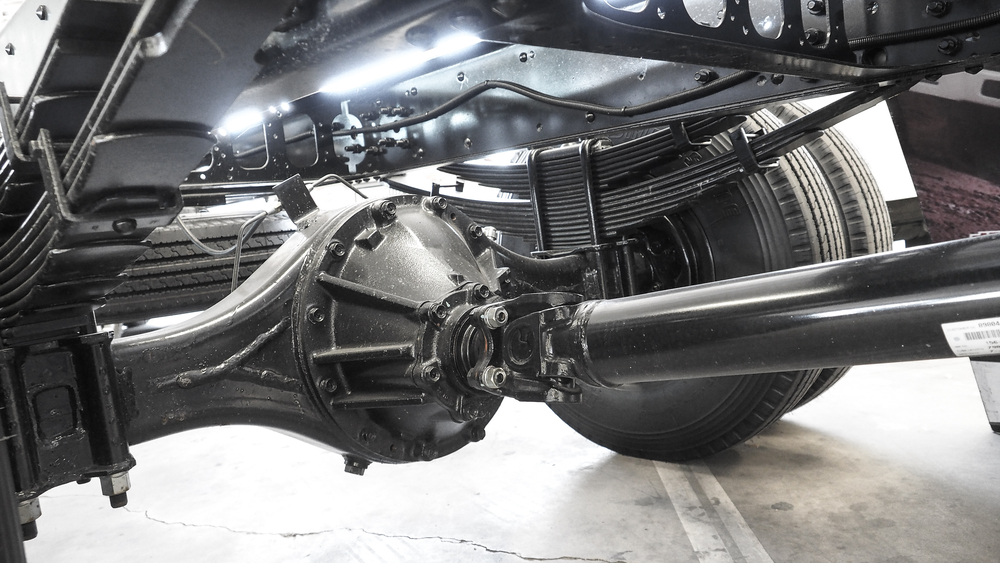

When it comes to the heavy-duty work performed by 18-wheelers, the axles are among the most critical components ensuring safe and efficient operation. A semi-truck’s axles bear the massive weight of cargo, transfer power from the engine to the wheels, and help maintain stability. Despite their robust design, axle failures are not uncommon and can lead to significant downtime, costly repairs, and safety hazards. Understanding the reasons for axle failure can help fleet managers and truck drivers take preventive measures, ensuring a well-maintained axle system.

The Importance of Semi-Truck Axles

Axles play a vital role in the performance of an 18-wheeler. A typical semi-truck axle is built to endure extreme forces, but over time, wear and tear or other issues can compromise its reliability. These failures can result in accidents or mechanical breakdowns that disrupt logistics and pose dangers to drivers and others on the road.

A well-maintained axle is essential for safety, fuel efficiency, and compliance with regulatory standards. Regular inspection and proactive maintenance are necessary to ensure that axles perform optimally under challenging conditions.

Common Causes of Axle Failures in Semi-Trucks

Axle failures are often the result of cumulative damage caused by various factors. Below are the most common reasons why semi-truck axles fail:

1. Overloading

One of the primary causes of axle failure in semi-trucks is overloading. Axles are designed to carry a specific weight, and exceeding this limit can place undue stress on the system. Over time, excessive loads can weaken axle components, causing cracks, deformation, or complete failure.

Preventive Measures for Overloading:

- Always adhere to the manufacturer’s load ratings.

- Distribute weight evenly across all axles.

- Use weigh stations to ensure compliance with legal weight limits.

2. Improper Maintenance

Neglecting regular maintenance is a leading contributor to axle failures. A well-maintained axle system includes properly lubricated bearings, tight bolts, and undamaged seals. Failure to address these aspects can lead to overheating, corrosion, or misalignment.

Maintenance Tips:

- Perform routine inspections of axles and their components.

- Check for leaks, rust, or unusual noises.

- Replace worn-out parts before they fail.

3. Driving on Poor Road Conditions

Potholes, uneven roads, and debris can put tremendous stress on a semi-truck’s axles. Sudden jolts from hitting large obstacles can bend or crack the axle, leading to long-term damage if not addressed.

Best Practices for Bad Roads:

- Reduce speed when driving on rough terrain.

- Avoid abrupt maneuvers or oversteering.

- Report hazardous road conditions to relevant authorities.

4. Manufacturing Defects

Although rare, manufacturing defects can cause axle failure. Substandard materials, design flaws, or improper assembly during production may lead to weak spots in the axle. These defects often become apparent under heavy loads or during prolonged use.

How to Address Manufacturing Defects:

- Choose reputable brands for replacement axles.

- Verify the warranty and certification of parts.

- Conduct thorough inspections of new axles before installation.

5. Corrosion and Rust

Axles are frequently exposed to moisture, road salts, and other corrosive elements, especially during winter months. Over time, these elements can cause rust and corrosion, weakening the axle’s structure and making it more susceptible to failure.

Preventive Strategies for Corrosion:

- Wash the undercarriage regularly, especially after exposure to salt or chemicals.

- Apply rust-proof coatings or treatments.

- Store vehicles in dry, climate-controlled environments when not in use.

6. Improper Installation or Repairs

Improper installation or subpar repairs can lead to misaligned axles or weakened components. Whether it’s a loose bolt, incorrectly fitted bearing, or improperly tightened hub, such mistakes can cause premature wear or catastrophic failure.

Ensuring Proper Installation:

- Hire certified mechanics for axle repairs.

- Follow manufacturer guidelines during installation.

- Use high-quality tools and replacement parts.

7. Fatigue and Wear Over Time

Even the most durable axles have a finite lifespan. Continuous use, especially under heavy loads, causes gradual wear and tear. Metal fatigue can develop over time, making axles more vulnerable to cracks and fractures.

Extending Axle Lifespan:

- Schedule regular maintenance to identify early signs of wear.

- Rotate tires to distribute stress evenly.

- Upgrade axles when necessary to meet operational demands.

8. Inadequate Lubrication

Axles rely on proper lubrication to reduce friction between moving parts. Insufficient lubrication can lead to overheating and increased wear, eventually causing axle failure.

Tips for Proper Lubrication:

- Use manufacturer-recommended lubricants.

- Check lubricant levels regularly.

- Replace contaminated or degraded lubricants promptly.

9. Excessive Torque or Overloading During Acceleration

Excessive torque, particularly during rapid acceleration or heavy braking, can strain axles beyond their capacity. This is especially common in situations where drivers push the truck to its limits in terms of speed or cargo weight.

Avoiding Excessive Torque:

- Accelerate gradually, avoiding sudden throttle applications.

- Use appropriate gears for load and terrain conditions.

- Train drivers in safe driving practices.

Signs of a Failing Axle

Detecting early signs of axle failure can prevent costly breakdowns and ensure driver safety. Here are some warning signs to watch for:

- Unusual Noises: Clunking, grinding, or clicking sounds may indicate worn-out components.

- Vibration: Excessive vibration during driving can point to misalignment or structural damage.

- Leaking Fluids: Leaks near the axle area suggest damaged seals or bearings.

- Uneven Tire Wear: Irregular tire wear often signals axle misalignment or damage.

- Difficulty Steering: A bent or damaged axle can affect steering stability and control.

The Role of Regular Inspections

Routine inspections are essential for ensuring the longevity and reliability of a semi-truck’s axle system. During inspections, mechanics should:

- Check for visible damage, such as cracks or bends.

- Test axle alignment and balance.

- Verify the condition of bearings, seals, and other components.

- Monitor axle temperature during operation to identify overheating issues.

By identifying problems early, you can address them before they escalate into major failures.

Conclusion

Semi-truck axles are subjected to extreme demands every day, and failures can have significant consequences. Overloading, poor maintenance, road conditions, manufacturing defects, corrosion, and improper repairs are among the most common reasons why axles fail. By understanding these causes and taking proactive measures to maintain a well-maintained axle system, fleet managers and drivers can extend the lifespan of their vehicles and ensure safety on the road.

Investing in regular maintenance, proper driving practices, and high-quality replacement parts is essential for preventing axle failures. A well-maintained axle not only enhances performance and reliability but also reduces the risk of accidents and costly downtime. Stay vigilant, inspect regularly, and prioritize axle care to keep your 18-wheeler rolling smoothly.